Planetary gears are widely used inside power transmissions, especially in the transport or heavy industry: they provide a substantial reduction ratio while keeping a minimal volume, which is a benefit for the industry in an ecological point of view. Yet, this diminution in volume comes with an augmentation of the thermal mass power inside the transmission.

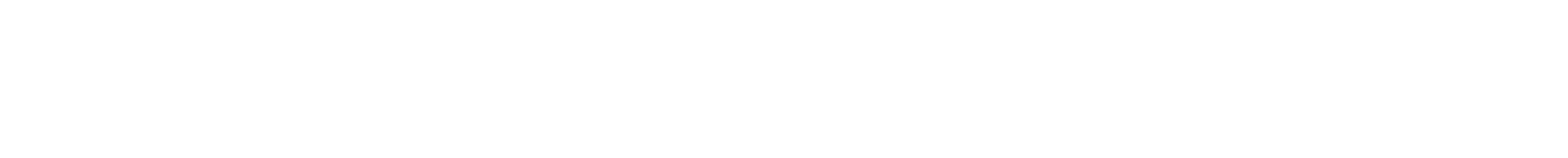

When this transmission is splash lubricated, the thermal response of the system becomes a crucial problem because it cannot provide the sufficient cooling that the injection lubrication does. Moreover, it adds up another source of power loss with the drag loss of the

rotating parts, that heats the transmission as well. That type of lubrication is nonetheless easy to maintain unlike the injection.

Thus, the thermal modeling of such transmission seems a necessity in order to estimate the conditions until this type of lubrication is viable, especially when heavily loaded. The literature provides little to no model to predict to drag power losses in a planetary

gear set, especially since it mainly dealt with oil injected ones.

So, the first step is to develop a dedicated power loss prediction model for drag losses occurring in a planetary gear set. This has been done using a dedicated test rig. The second step uses this prediction model to develop a thermal model of an industrial reducer, using the thermal network method. This has been done in order to optimize multiple aspects: the impact of the tribology on the thermal response of the reducer and the optimization of the oil volume inside the splash lubricated reducer.

In regards to these results, the power loss prediction model for drag loss seems to be robust; the thermal model simulates correctly the thermal response of the reducer and is a powerful tool to optimize the industrial reducer.